What's differences of COB & SMD LED Chips?

It's important to choose suitable Led chips for the LED lights. When our customers want to light up and decorate their places they will consider the light colors lumens and LED chips of the light. So what's the LED chips meaning? There are two prominent contenders in the LED (Light-Emitting Diode) arena are COB (Chip on Board) and SMD (Surface Mounted Device)

Yuanyeled always provides high quality led chips for our products such as led wall washer lights, led bar light, led flood light, led underwater light, led wall light, bollard lights and so on.

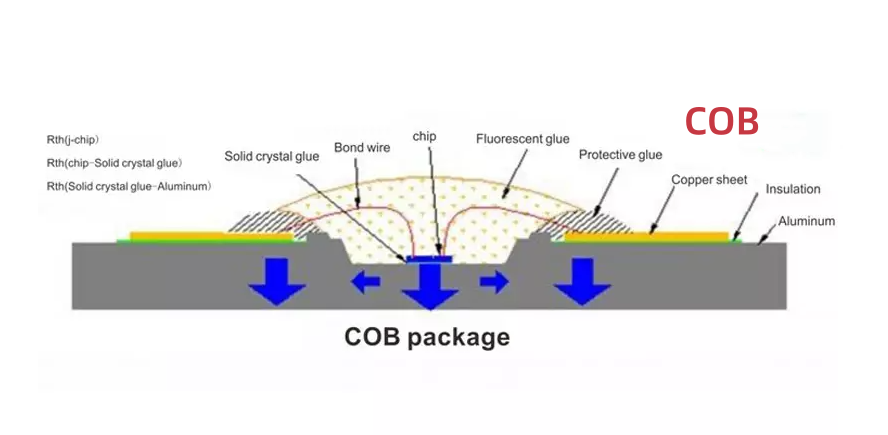

What is COB chips?

Multiple LED chips are directly mounted onto a substrate, allowing for a compact and high-density light source. The design typically integrates the chips without individual lensing and often uses a phosphor coating to convert light to the desired color.

The substrate material and heat sink of COB LEDs exhibit excellent heat dissipation properties, ensuring that the heat generated by the chips is effectively conducted, resulting in low-temperature operation, prolonged LED life, and improved stability.

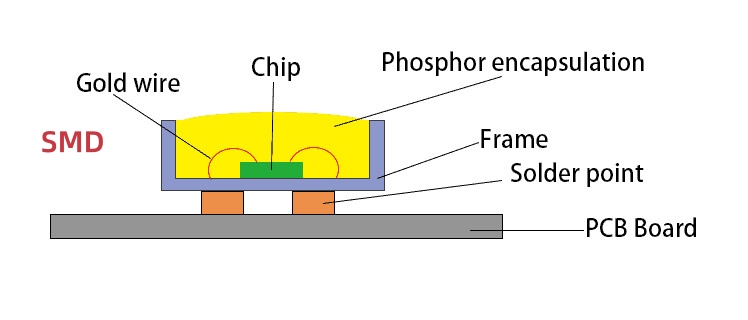

What is SMD chips?

Individual LED chips are encapsulated in a small package that can be mounted directly onto a circuit board.They can come in various shapes and sizes, allowing for flexibility in design and placement.

Moreover, SMD LEDs operate at lower voltages and currents, resulting in reduced energy consumption and heat generation, which contributes to their extended lifespan and improved stability. Additionally, the presence of three single-color LED units (red, green, and blue) within each LED enables SMD LEDs to achieve multi-color or full-color displays, providing versatility in lighting effects.

The main differences between LED SMD and COB

Difference size

SMD components are smaller, usually a few millimetres in length, width and height of a small square or rectangle, while COB components are usually larger than the SMD, Usually a chip isconnected to a PCB board.

Difference packing methods

SMD components can be welded to the surface of the printed circuit board (PCB), while COB components are multiple chips mounted directly on the board and bonded to a special glue with high thermal conductivity, high corrosion resistance, and high bonding strength.

Brightness

Generally, COB LEDs boast higher lumen output per watt, translating to brighter illumination. This makes them ideal for tasks requiring intense light.

Beam Angle

COB LEDs often offer wider beam angles, providing a more expansive area of illumination. SMD LEDs typically have narrower beam angles, suitable for focused lighting.

Color Rendering: Both COB and SMD LEDs can achieve excellent color rendering, accurately reflecting the true colors of objects. However, COB LEDs may have a slight edge in this area due to their more uniform light distribution.

Besides, COB LEDs boast superior heat dissipation due to their larger surface area. This translates to increased efficiency and potentially longer lifespans. SMD LEDs offer a wider range of color temperature options, allowing for greater design flexibility. It can achieve multi-color or full-color displays, thanks to the presence of three single-color LED units

So how to choose suitable LED SMD and COB chips?

Choose COB LEDs when

Brightness is crucial: COB LEDs produce significantly higher light output compared to SMD LEDs, making them ideal for applications where intense illumination is essential.

Uniform light distribution is essential: COB LEDs offer a smoother, more uniform light distribution, eliminating visible shadows and hotspots. This makes them suitable for task lighting, architectural lighting, and applications where a seamless visual appearance is desired.

Wider beam angle is needed: COB LEDs typically have a wider beam angle, spreading light across a larger area. This makes them suitable for general illumination, stage lighting, and applications where broad coverage is required.

Heat dissipation is not a major concern: COB LEDs generate more heat compared to SMD LEDs. Ensure the application area has adequate heat management if using COB LEDs.

Choose SMD LEDs when

Cost-effectiveness is paramount: SMD LEDs are generally more affordable than COB LEDs, making them a cost-effective choice for budget-conscious applications.

Compactness is crucial: SMD LEDs are smaller and more compact than COB LEDs, making them suitable for applications where space is limited.

Versatility in color temperature is needed: SMD LEDs offer a wider range of color temperature options, catering to diverse lighting needs.

Durability and reliability are essential: SMD LEDs are known for their durability and long lifespan, making them suitable for applications that require ruggedness and longevity.

Ultimately, the choice between COB and SMD LEDs depends on the specific requirements of the application. Consider factors like brightness, light distribution, beam angle, cost, compactness, versatility, and durability to make an informed decision.

We hope this comprehensive guide can help you understand more about LED SMD and COB chips when you choose the led light fixtures.

Yuanyeled as a led outdoor lights manufacturer and factory over 13 years experience specializing in producing high-quality customized DMX512 led stage lights with digital display and buttons, led wall washer lights, led bar light, led flood light, led underwater light, led wall light, led bollard lights, led garden lights, led point lihgts and RGB tube light.

Please contact us if you need to purchase or customize LED lights.

Shenzhen Yuanyeled Co.,Ltd. is a professional company, was established in 2011 based in Shenzhen, China with over 10-year experience in LED lighting industry starting with LED encapsulation.

CONTACT US

Email: rice@yuanyeled.com

Tel: +86-19925346944

WhatsApp: +86-19925346944

ADD: Floor 8th, building 8, Langxia third industrial zone, Songgang town, Baoan district, Shenzhen city, China.